Electroless Nickel Plating: Enhancing Performance and Reliability

Electroless nickel plating is one of the most unique types of plating that we offer here at Reid Metal Finishing. This type of nickel plating offers several advantages and is popular due to its incredible versatility, as the coating can be applied to nearly any metallic substrate, without the usual limits of coating thickness.

The electroless nickel plating process

Electroless Nickel Plating (ENP) is a process that deposits a nickel alloy coating onto a metal substrate through chemical reduction–and without the use of an electric current typical of other plating processes. Using a chemical reduction agent, the chemical bath causes a reaction that deposits nickel ions onto the substrate. While it does require the use of phosphorus additives in order to deposit nickel ions, the process doesn’t require the constant filtration to keep debris in the bath from adhering to the surface.

ENP is an incredibly versatile coating, and the amount of phosphorus plays a large role in the characteristics of the coating. Higher phosphorus content in the bath will lead to better corrosion resistance as a result, but also less hardness, and the reverse is true as well–lower phosphorus content results in higher surface hardness, but less resistance to corrosion. This allows the user to adjust the amount of phosphorus in order to get the properties that they want.

The benefits of electroless nickel plating

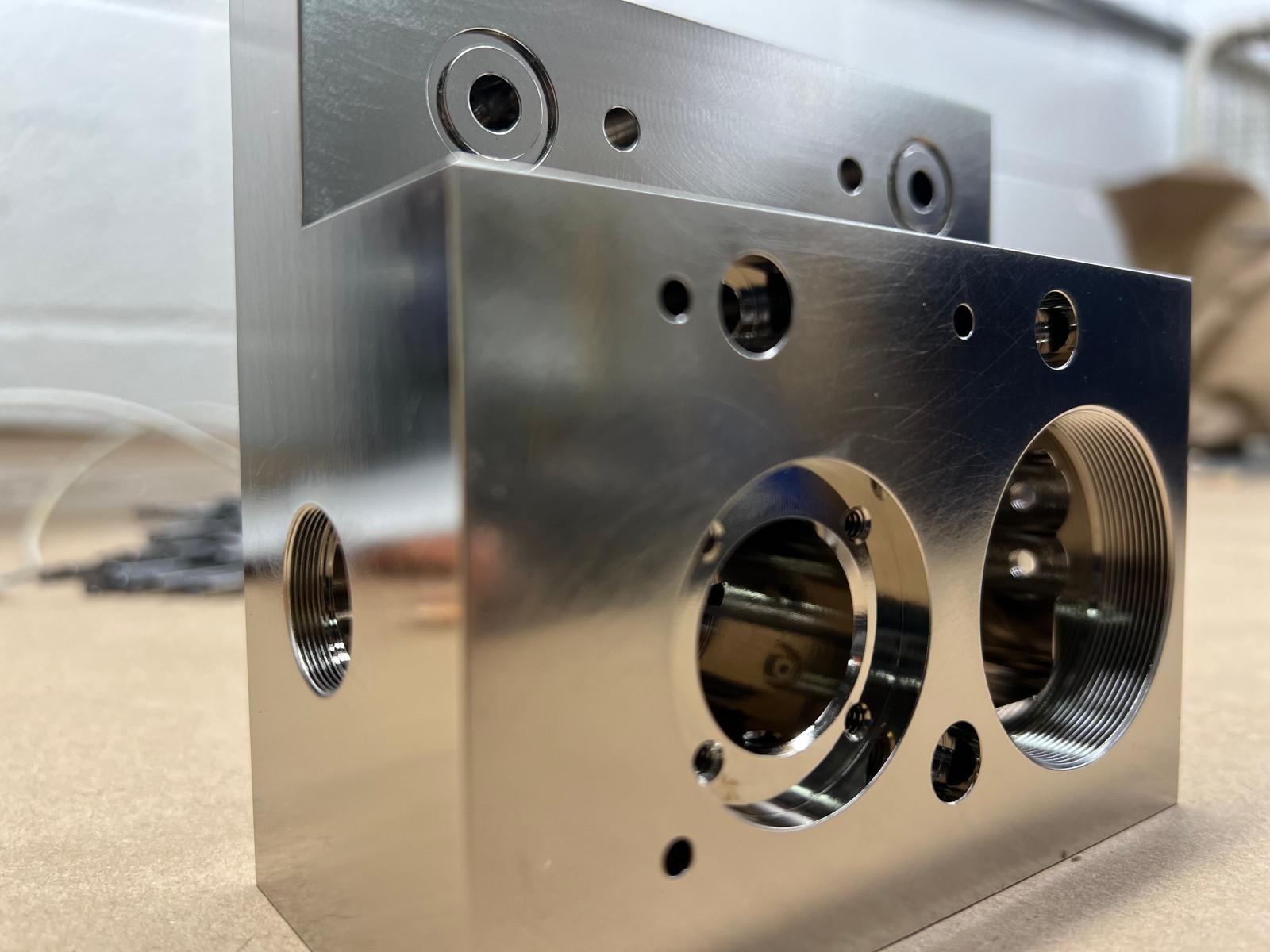

Electroless nickel plating is a cost effective coating that is popular for applications where a uniform coating is needed on components with slots, holes, and the insides of tubing. These types of applications tend to pose more of a challenge for electrolytic deposits.

ENP offers the best corrosion resistance in environments when the parts will be exposed to salt water, carbon dioxide, high oxygen content, and hydrogen sulfide. The coating is highly resistant and reliably long-lasting, offering a lower-cost alternative to corrosion-resistant alloys.

The main benefit of course is this coating’s versatility and durability. The phosphorus content of the coating can be adjusted in order to get the right level of hardness or corrosion resistance. Combined with the increased ductility that ENP will impart onto the substrate, this type of coating has become popular in many high-stress applications across the Aerospace, Defense, Industrial, and Automotive industries.

There are several other benefits as well, including improved electromagnetic interference shielding, popular in aerospace and defense applications, and enhanced lubricity for automotive and industrial equipment. Overall, ENP has proven time and again to enhance part performance and life cycles for more reliable operation in the long run.

Looking for a quality supplier of metal finishing services?

Reid Metal Finishing has one of the largest arrays of metal finishing services, including electroless nickel plating and several types of electrolytic plating, anodizing, chemical film, and more. For more information, check out our website or contact us.