Chem Film 101: Understanding the Basics of Chromate Conversion Coating

Chromate Conversion Coating or Chem Film is a common type of coating used to protect aluminum and other metals from corrosion. This easy and efficient type of metal finishing treatment is popular in Aerospace and Military equipment applications due to its excellent protection against corrosion and its ability to serve as a base for future coatings like paints and adhesives.

What is Chem Film?

Chem Film has a lot of names–Chromate conversion, Alodine, and Iridate–but all refer to the same process of finishing aluminum, or making it less affected by the environment around it without affecting the material underneath. The coating is mainly made of a chromate, and can be applied directly to the surface of aluminum.

While chem film is usually applied to aluminum components, it’s also an excellent finish for copper, cadmium, tin, magnesium, zinc-plated steel, and iron. Regardless of the metal, it’s an excellent base for many other coatings, while still offering high corrosion resistance just on its own.

Common Types of Chem Film

Chem film has four basic types, each distinguished by its chemistry and the standards set for it:

- MIL-DTL-5541

- AMS-2473 & 2474

- MIL-C-81706

- AMS-C-5541

The MIL-DTL category of chromate conversion coatings are the most commonly used and has two Types.

- Type I refers to sodium dichromate or hex chrome films, and is known for its composition of hexavalent chromium. While this initially was widely used, Type I Chem Film was replaced by the development of comparable substitutes for the more dangerous hexavalent chromium.

- Type II or hex-free chromate is now the preferred version of the MIL-DTL category, replacing hexavalent chromium with materials such as zirconium, titanium, or trivalent chromium. Type II has also gained popularity because its application process tends to be faster and more efficient than the application of Type I.

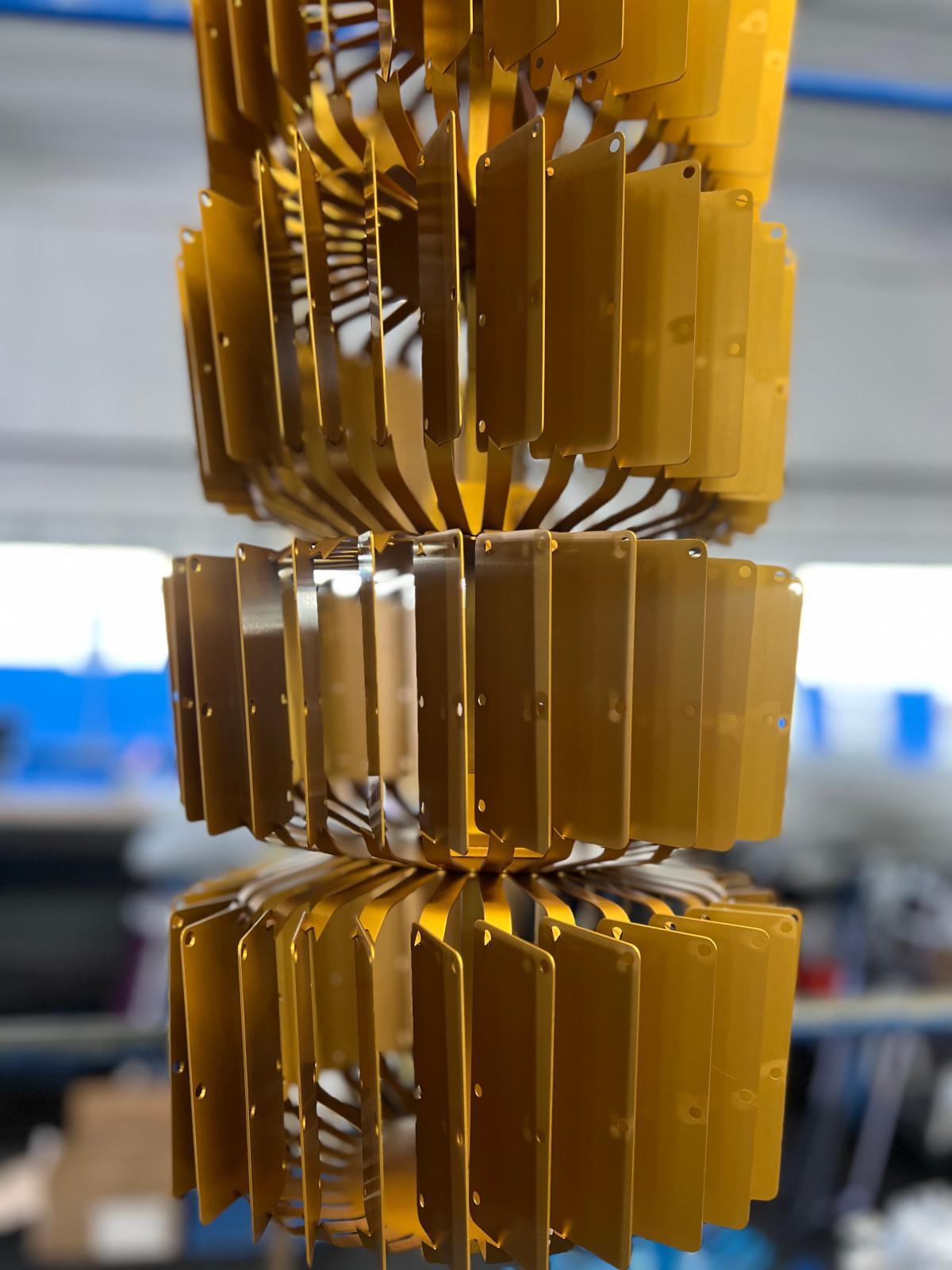

The Chem Film Process

The chem film process is fairly simple, and though it may vary between different suppliers.

- First, all dirt, residue, and debris is cleared from the parts’ surfaces and the parts are thoroughly rinsed.

- Once the parts are clean, they can be treated in an acid or alkaline etch to remove any alloying elements that could interfere with the chemical reaction of the coating. The parts are fully rinsed in water once more.

- After the parts have been etched, they’re treated again, this time in an acid that will remove the naturally occuring oxide film on the surface. The parts are then rinsed again before being sent to the final step.

- Now that the parts have been fully cleaned, etched, and deoxidized, the chem film coating can be applied. Following the conversion coating, the parts are rinsed a final time and dried.

The benefits of Chem Film

Chem film coatings have several advantages. First, they tend to be more economical and cost efficient than other processes, as they require fewer steps and less labor. Chem films are also very easy and quick to apply, and serve as a good base or primer for later coatings, such as paints. They can also be combined with Type II anodization to repair small damages to anodized surfaces. In addition, chem film coatings are very thin and nearly immeasurable, so they have little to no effect on part dimensions.

The applications of Chem Film

Chem film treatments are popular in a wide range of industries, including industrial manufacturing, electrical equipment, and defense manufacturing, but they are most commonly associated with the Aerospace industry. Chem films, like we’ve mentioned before, aren’t applied just by themselves–they’re often used as a primer or substrate that other coatings can be added to later on. They can prevent fingerprinting on softer metals and offer reliable electrical connections between parts as well.

Looking for a supplier of chem film coatings?

Reid Metal Finishing is an AS9100 certified and Nadcap accredited supplier of several different metal finishing treatments, including chem film. Check out our website to learn more about what we can do for you!