Supporting Our Community and Our Heritage

Recently, the team at Reid Metal Finishing came together to support our local Heritage Museum. Every summer, we come together to work on a big project aimed at helping our community. This summer, on July 25th-26th, we helped out our neighbors at the Heritage Museum of Orange County with cleaning up their outdoor facilities!

Advancements in Non-Destructive Testing Technology: Improving Inspection Precision

Reid Metal Finishing (RMF) employs many different methods of quality control and inspection in our facility, one of which being non destructive testing. Commonly referred to as NDT, this term refers to any sort of testing or analysis process that evaluates the quality and structural integrity of a manufactured product or a finished process without […]

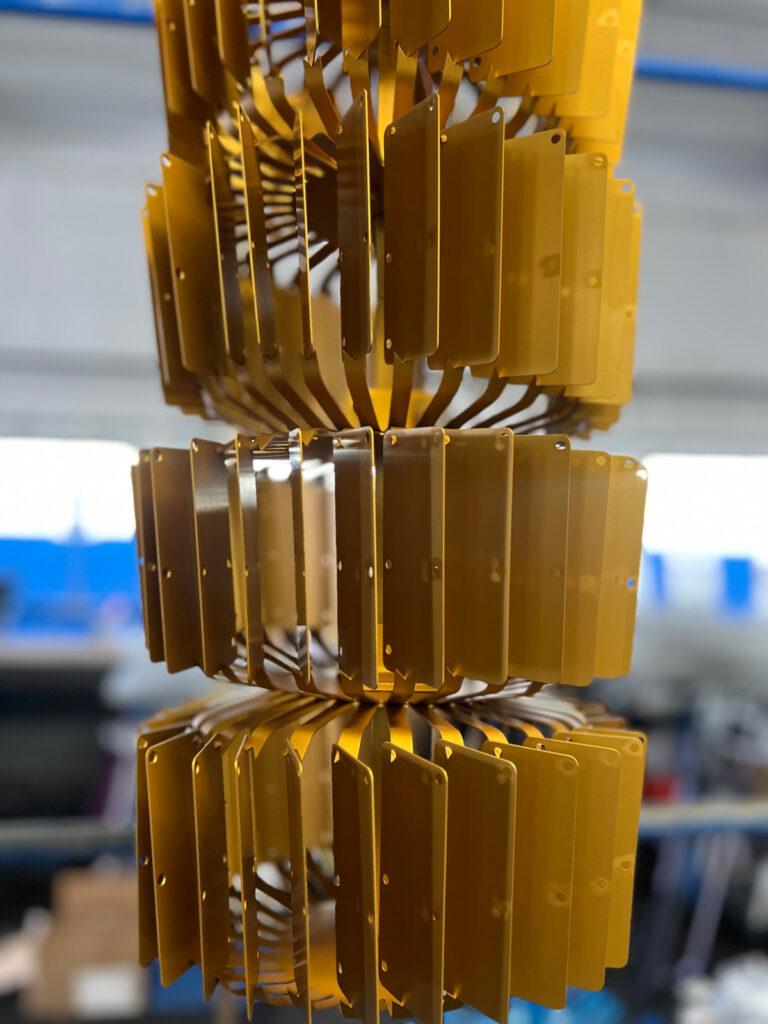

Colorful Possibilities: A Deep Dive into Aluminum Anodizing Dyes and Finishes

Aluminum components are anodized for a number of reasons–corrosion resistance, improved durability, wear resistance. There is another benefit that anodization can offer that has less to do with functionality and longevity and more to do with aesthetics. Anodization offers a method for electrochemically coloring an aluminum surface for a long lasting and fade resistant surface […]

Chem Film 101: Understanding the Basics of Chromate Conversion Coating

Chromate Conversion Coating or Chem Film is a common type of coating used to protect aluminum and other metals from corrosion. This easy and efficient type of metal finishing treatment is popular in Aerospace and Military equipment applications due to its excellent protection against corrosion and its ability to serve as a base for future […]

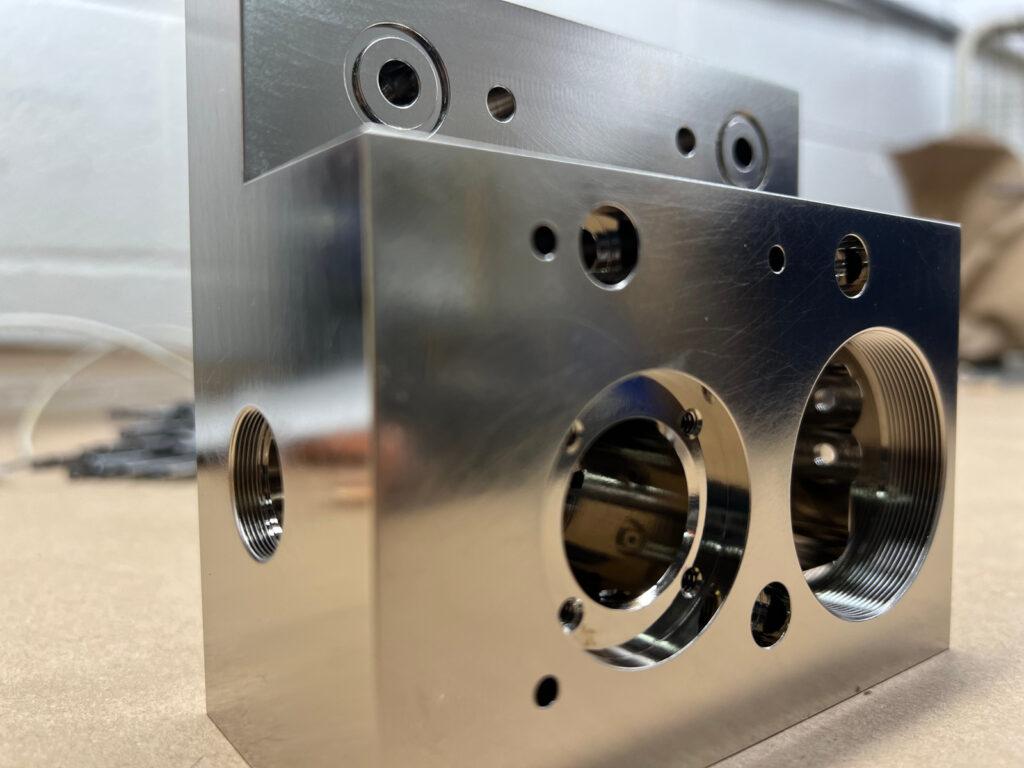

Electroless Nickel Plating: Enhancing Performance and Reliability

Electroless nickel plating is one of the most unique types of plating that we offer here at Reid Metal Finishing. This type of nickel plating offers several advantages and is popular due to its incredible versatility, as the coating can be applied to nearly any metallic substrate, without the usual limits of coating thickness. The […]

Zinc Nickel Plating: Superior Corrosion Protection for Harsh Environments

One of the many different metal finishes that Reid specializes in is zinc-nickel plating. While a relatively recent type of coating compared to others, zinc-nickel plating has proven to be an excellent finish, suited for challenging environments, exhibiting a corrosion resistance that’s comparable to the more expensive cadmium plating. What is zinc-nickel plating–and how does it […]

Cadmium Plating Best Practices: Ensuring Quality and Compliance

Cadmium plating is one of the many services that Reid Metal Finishing offers, and we understand better than anyone the importance of quality, safe practices when it comes to this type of metal plating. An overview of cadmium platingCadmium plating is a soft, sacrificial coating that can be deposited onto a variety of metals such as […]

A look at Sulfuric Anodizing: how it works and where it’s used

Sulfuric anodizing is one of the many types of finishing services that we offer at Reid Metal Finishing. This type of aluminum anodization is unique, offering both excellent durability and aesthetics, making the coating an excellent choice for a wide range of applications. Type II Anodization Sulfuric acid anodization, also known as Type II anodizing, […]

Quality Assurance in Metal Finishing

How Reid Metal Finishing Strives to Ensure ExcellenceMetal finishing techniques are common and valuable ways to improve the quality, corrosion and wear resistance, and even the aesthetics of metal parts. Metal finishing companies are often one of the last steps in ensuring the quality of a metal product before it’s shipped off to be installed […]

Reid Metal Finishing’s TJ Grandcolas recognized as a member of 40 Under 40: Class of 2023

Reid Metal Finishing owner TJ Grandcolas was recently recognized by Products Finishing as part of their 40 under 40 class of 2023.