At Reid, we understand the ins and outs of many different plating services. One of the more common types of plating that we perform is electroless nickel plating. This involves bathing components in a specially created solution that triggers the plating reaction.

At Reid, we understand the ins and outs of many different plating services. One of the more common types of plating that we perform is electroless nickel plating. This involves bathing components in a specially created solution that triggers the plating reaction.

A brief introduction to electroless nickel plating

The majority of plating is often done through a process called electroplating, which uses an electric current to trigger the reaction that causes a specific deposit to form a barrier on a metal. However, some specific types of plating, Nickel being one, can be performed without the use of an electric current. This is referred to as Electroless Nickel Plating.

The majority of plating is often done through a process called electroplating, which uses an electric current to trigger the reaction that causes a specific deposit to form a barrier on a metal. However, some specific types of plating, Nickel being one, can be performed without the use of an electric current. This is referred to as Electroless Nickel Plating.

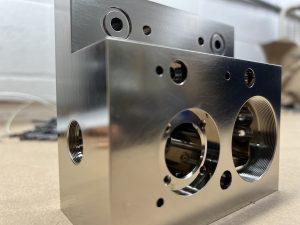

As mentioned above, to complete the plating process without an electric current, we prepare a special solution in which we then bathe the components. This solution triggers the reaction that binds the nickel to the part, and forms the protective coating. While electroless nickel plating cannot offer as enhanced conductivity and heat resistance as regular Nickel plating, it does provide a more uniform deposit thickness and superior corrosion resistance due to the use of a phosphorus additive in the process.

As mentioned above, to complete the plating process without an electric current, we prepare a special solution in which we then bathe the components. This solution triggers the reaction that binds the nickel to the part, and forms the protective coating. While electroless nickel plating cannot offer as enhanced conductivity and heat resistance as regular Nickel plating, it does provide a more uniform deposit thickness and superior corrosion resistance due to the use of a phosphorus additive in the process.

Some other benefits of electroless nickel plating include:

- Improved corrosion resistance

- Increased hardness

- Enhanced durability and EMI shielding

- Increased ductility

- Greater coating versatility—it can be applied to nearly any metallic substrate without any limits on the thickness of the coating

Electroless Nickel plating is often used on components in aerospace, defense, industrial, and automotive applications. This type of plating is especially beneficial for high-stress applications due to its ductility, hence its popularity in particularly harsh applications of the Defense and Aerospace sectors.

Choose Reid Metal Finishing for your plating needs

Reid Metal Finishing maintains a complement of equipment to provide high-quality plating to all of our customers. We provide a variety of different plating options, including Nickel, Zinc-Nickel, Cadmium, and passivation. If you have any questions for us or if you’re ready to get started, then don’t hesitate to contact us today!